Recycling, the circular economy, reusability and sustainability are among the greatest challenges of our time. Leaving a world worth living in for future generations is certainly one of the most complex challenges facing the global community. As sustainability has always been a particular concern for us at esbe plastic, we began actively addressing this issue 20 years ago.

We have had an internal sustainability study since 2000. The annual life cycle assessment provides us with valuable consumption figures in terms of energy requirements, heating oil, electricity, gas and water consumption and gives us the opportunity to regulate our CO2 emissions.

We introduced an internal waste management system back in 2007, which not only enables seamless recycling of internal waste, but also combines this with significant energy savings. For example, our PP (polypropylene) production waste is fed back into the cycle as PIW (= Post Industrial Waste) using a fully automated extraction process.

Extrusion and production are therefore 100 % waste-free.

Thanks to this process, our PP films have an intrinsic recycled content of 35 to 40 %. And it gets even better: our esbe PP monofilm in natural/transparent is 100 % recyclable and can therefore be easily recognised as PCW (Yellow Bag), sorted and returned to the cycle, for example through material recycling.

Our PP monofilm was assessed as follows in terms of recyclability:

Recyclable material content: 100%

Sortability: 100%

Usability: 100%

In addition to these sustainable endeavours in production and peripherals, a new and modern photovoltaic system has enabled us to produce 10 percent of our energy requirements ourselves since 2024. This is environmentally friendly and sustainable. For even more sustainability at esbe plastic. Further expansion is planned.

Certifications

to improve recyclability

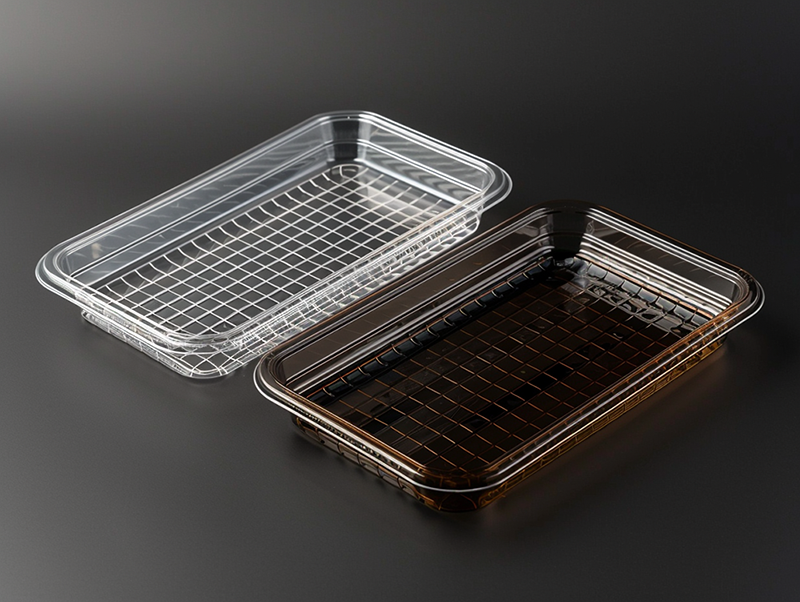

Together with our customers, we set ourselves the goal of making packaging as sustainable as possible. We examine possible material reductions and the switch from coloured to transparent blisters. In this way, we ensure the recyclability of our packaging and increase the chance that it can be recycled and reprocessed in practice.

Waste-free production

Efficient waste utilisation is important to us, which is why we use polypropylene, which is recyclable and environmentally friendly.

By returning our entire production waste to the material cycle, we achieve largely waste-free production and save CO2.

esbe PP

What is behind the esbe PP film?

- esbe PP film is not a laminated film but a mono film

- esbe PP film is 100 % recyclable

- esbe PP film has an post industrial regenerate content of 35-40 %

This applies to all trays supplied in PP film from esbe plastic GmbH.

PP films are in demand in transparent and also coloured as post-consumer regranulate and are already used for various applications.

We are also happy to answer any questions you may have about reducing the amount of material on your trays or changing from coloured to transparent.

esbe PET

The PET film we use is a monofilm that is 100 % recyclable.

The PET films are available in transparent, coloured and metallised as 100 % virgin material and as film with recycled content. This applies to all trays supplied in PET film from esbe plastic GmbH.

PET films are in demand and used in transparent versions as post-consumer regranulate.

We are also happy to answer any questions you may have about reducing the amount of material in your trays or switching from coloured to transparent.